A Superior Energy Services Company

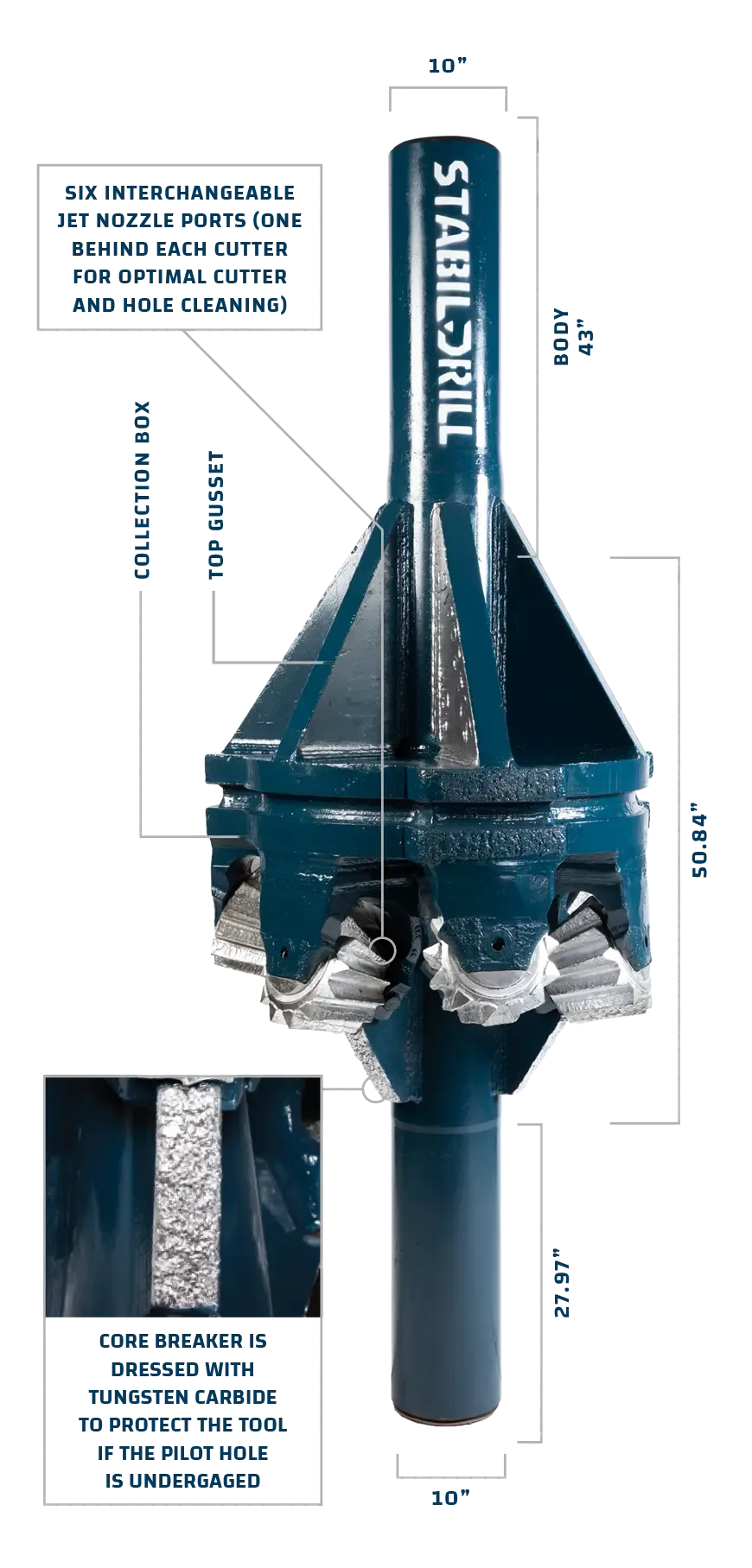

At Stabil Drill, our BHA experts help you specify the perfect design for strong hole creation. All of our hole openers are engineered and made in-house from AISI 4145H fully heat-treated alloy.

Our tools feature forged bodies, thick collector boxes, cast iron mounts, 24/32 Series 95 Smith jets, and optional carbide-milled teeth and inserts. They also come with hard-facing alloys to optimize hole development and enable cutter changes in the field.

Stabil Drill’s hole openers are engineered for strength, stability, and precision enlargement. Whether fixed-blade, sealed bearing, or specialty Devil Drill™, every tool is built in-house from fully heat-treated AISI 4145H alloy for dependable downhole performance. With replaceable cutters, customizable designs, and high-flow jet configurations, our openers deliver optimized hole quality and long tool life in even the most demanding formations.

For...

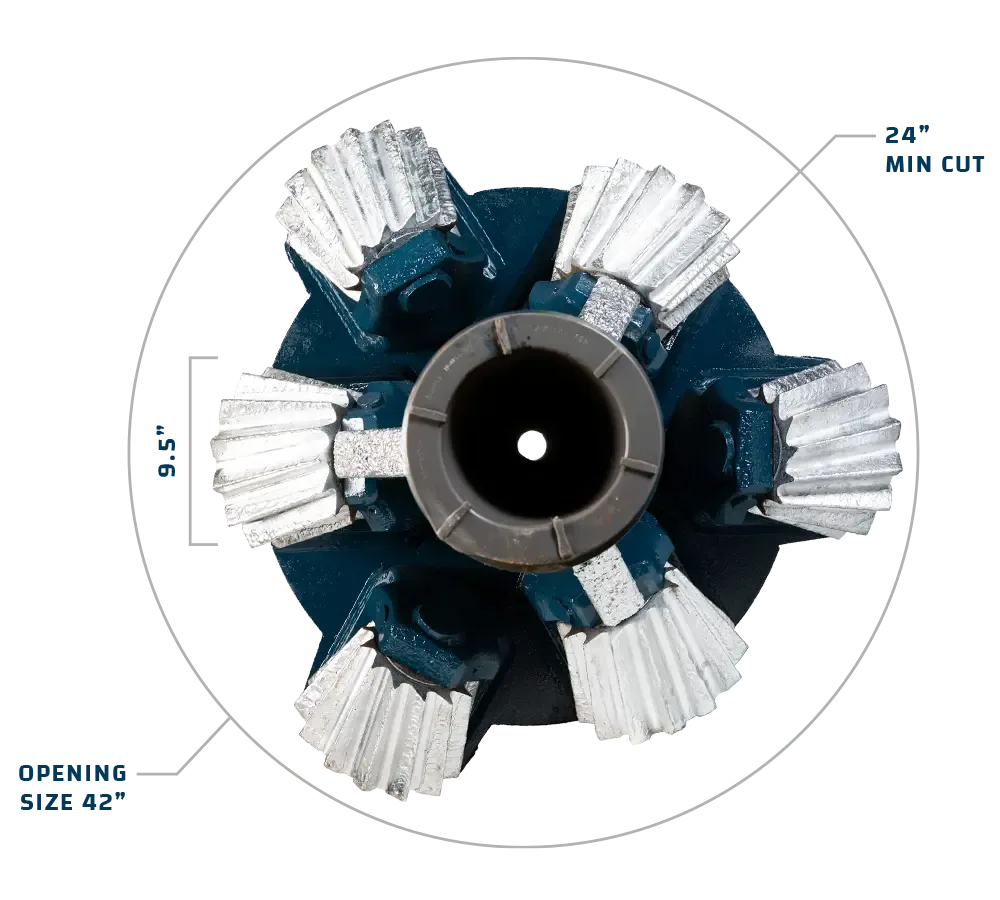

| Fishing Neck OD | 9.5" |

| Fishing Neck Length | 43" |

| Connection Up | 7-5/8" Reg API PIN |

| Internal Diameter | 2.813" |

| Minimum Pilot Hole | 24" |

| Opening Size | 42" |

| Body Material | 4145H Mod |

| Number of Cutters | 6 |

| Cutter Types | Sealed Bearing |

| Number of Nozzles | 6 |

Featuring solid, one-piece construction and either milled tooth or tungsten carbide cutters, these tools deliver the stability and reliability you need to execute the drill plan with confidence. Accommodates solid or circulating bullnoses.

This design optimizes hole cleaning through use of a box collector that creates even fluid flow directly onto the unit's cutters. Accommodates up to 60”, and features either three or four cutters. Custom sizes and designs available; ask your Stabil Drill representative for details.

With no moving parts that could fail and create unnecessary trips or NPT, the Devil Drill wipes the hole clean for easy casing installation to the bottom. Often deployed directly after horizontal mud motor runs, the Devil Drill™ features blade edges tipped with tungsten carbide chips.

Simultaneously allows hole enlargement while drilling. Allows underreaming of a hole larger than the ID above the casing.

Designed to eliminate key seat issues, this tool has no moving parts and it runs while you continue to drill— eliminating the need for a special trip to eliminate tight spots.

See how customers have unlocked success and maximized ROI with our tools.